LG Electronics'(LG) home appliance manufacturing plant in the United States has been selected as a world-leading Lighthouse Factory by the World Economic Forum (WEF).

The million-square-foot factory in Clarksville, Tennessee – the U.S. production base for LG’s award-winning washers and dryers – is the industry’s first home appliance plant in the United States to join the WEF’s global network. It also is the company’s second Lighthouse Factory, following the LG Smart Park in Changwon, South Korea, which was selected by the WEF last year.

Also Read: COMPLY adds technology, operations and finance expertise to expanded…

A “Lighthouse Factory” is recognized by the WEF for its role in shaping the future of manufacturing through the integration of Internet of Things (IoT), big data, artificial intelligence (AI), robots and other Fourth Industrial Revolution technologies. Since 2018, the WEF has selected and added global factories to its network twice a year.

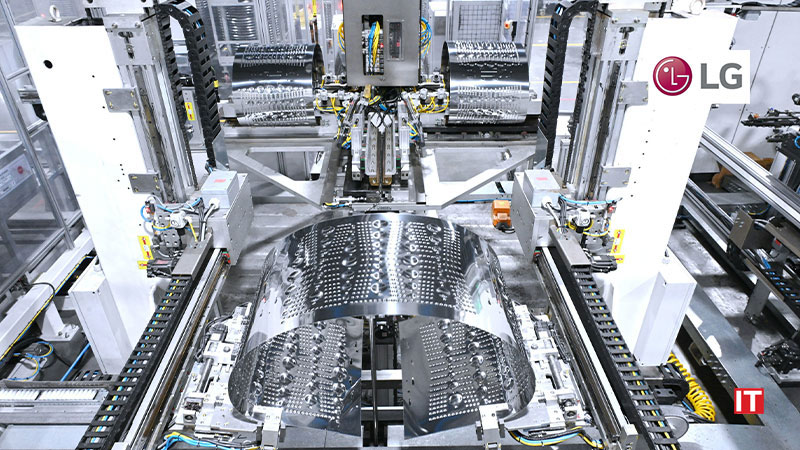

LG‘s world-class autonomous factory in Tennessee utilizes advanced digital technologies from AI and big data to IoT and robots. Completed at the end of 2018, the facility now operates three production lines for front-load and top-load washing machines and dryers. With an annual production capacity of 1.2 million washers and 600,000 dryers, the plant proactively responds to changing North American demand through local production. More than 900 people work at the LG home appliance factory in Montgomery County, Tenn.

Featuring a completely integrated production system and streamlined process, each line carries out the entire manufacturing process of new models, from making the parts to assembly and packaging. In addition, strict quality conditions are applied to all assembly lines to heighten quality across the board, from parts to finished products.

The LG Tennessee factory boasts a fully autonomous logistics system with 166 automated guided vehicles (AGVs) that transport parts around the plant. With three times more AGVs than the LG Smart Park in South Korea, these robots improve overall productivity by freeing up people for other tasks.

With the integration of parts production such as metal press processing, plastic injection molding, and painting — including LG’s own intelligent injection molding system — the company has increased component productivity by 21 percent.1 In addition, the plant recognizes and responds in advance to potential productivity issues through an advanced detection system. By applying data-based AI technology that accurately predicts washing machine performance, the number of tests and energy consumed during testing are reduced by 22 percent, while the defect rate has been reduced by more than 61 percent via quality optimization.2

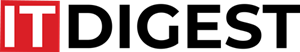

The plant is also maximizing workplace safety and operational efficiency by using robots for complicated, potentially dangerous tasks, such as assembling and lifting heavy parts and welding.

To further improve efficiency, LG plans to establish a 5G connectivity network across the facility in the second half of this year, creating an environment where its many AGVs can transport materials faster and more accurately based on stable, uninterrupted communication. LG will also introduce Autonomous Mobile Robots that navigate the expansive facility with ease to enhance its logistics system.

LG’s commitment to sustainability can be seen throughout the Tennessee factory, which transitioned to renewable energy completely in 2022. The plant also uses a high-efficiency utility infrastructure, which supplies the power, steam and heat necessary to produce LG’s home appliance products with the help of the company’s advanced Building Energy Control (BECON) solution.

SOURCE: PR Newswire